- Home

- About Us

-

Products

- Rebar

- Fabric

- Couplers

- Startabox/Continuity System

- Accessories

- Concrete, Plastic and Wire Reinforcement Spacers

- Construction Chemicals, Grouts, Mortars and Resins

- Gabion Baskets

- Groundwork and Slab Accessories

- Rebar Couplers

- Permanent Formwork,Column Formers and Formwork Accessories

- Site Safety and Test Equipment

- Waterproofing and Gas Barriers

- Lifting & Fixing Systems

- Spread Anchor System

- Precast Accessories

- Brickwork Products

- Shear Rail

- Diaphragm Wall and Piling

- Couplerbox

- Carpet Reinforcement

- Prefab

- *New* Wall Stability System

- Technical Services

- Downloads

- Contact

Startabox® - Reinforcement Continuity System

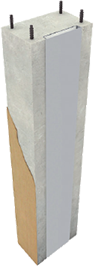

The Startabox system consists of specially selected, high yield reinforcing steel, housed in a fully perforated and hot dip galvanised carrier unit. The unit ends are sealed to prevent the ingress of concret

The reinforcement used is CARES Approved and cut and bent to conform to BS8666. The system is assembled in a BS EN ISO 9001 factory environment and the full system carries a CARES Technical Approval.

The product design ensures fast and easy faxing by nailing to the formwork or tying to the existing reinforcement. Bars are quickly bent out using the specifically designed re-bend tool.

When compared to traditional methods, the product offers a cost saving by means of a less labour intensive installation process and a simplification of formwork.

Most joints in concrete, on many different types of construction site, have the potential to be formed using Startabox. Startabox has been supplied to high rise commercial buildings, water treatment plants, hospitals, prisons, energy from waste facilities and many more types of construction site.

- Walls

- Brick Support Nibs

- Corbels

- Floor Slabs Corbels

- Balconies

- Launder Channels

- Stair Landings

- Precast Slab Interfaces

- Cantilever Slabs

- Stairway Applications

Installation

1. A startabox unit is installed by firstly nailing through the casing to the shutter face.The casing is annealed at points to make this operation easier.

2. With the startabox unit securely in place,concrete can be poured and the entire unit will become part of the first pour of the concrete structure.

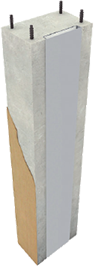

3. With the formwork struck,the Startabox lid and endcaps can now be removed and discarded.The lap bars contained inside the case will now be revealed for rebending.

4. With the Startabox opened, the lap bars can bent out using the correct tool and following the rebending procedure.

Startabox® - Standard Reinforcement Continuity System

Although most Startabox units are made to order using the engineers original rebar details, there are occasions when time pressures do not allow this and a quicker supply is required. Last minute drawing changes or rescheduling of pour sequences can require another solution.

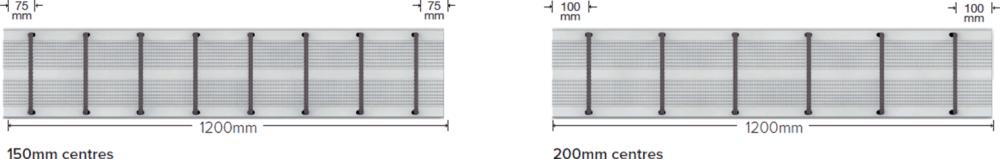

For this reason, a full range of Startabox standard units are kept in stock for rapid dispatch. The range covers a wide variety of wall and slab thicknesses and caters for the most popular bar diameters and bar centres. Standard units can be easily ordered using the relevant stock code below.

- Standard units containing 12mm rebar are supplied with 500mm lap bars.

- Standard units containing 16mm rebar are supplied with 650mm lap bars.

| Item Code | Box Width (MM) | Bar Dia (MM) | Bar Centres (MM) | Lap length (MM) | Single Hook Bar | Double 'U' Bar | Box Length (MM) | Pack Size |

|---|---|---|---|---|---|---|---|---|

| KH08102S801215 | 80 | 12 | 150 | 500 | ✔ | 1200 | Each | |

| KH08102S801220 | 80 | 12 | 200 | 500 | ✔ | 1200 | Each | |

| KH08102S111215 | 110 | 12 | 150 | 500 | ✔ | 1200 | Each | |

| KH08102S111220 | 110 | 12 | 200 | 500 | ✔ | 1200 | Each | |

| KH08102S111615 | 110 | 16 | 150 | 650 | ✔ | 1200 | Each | |

| KH08102S111620 | 110 | 16 | 200 | 650 | ✔ | 1200 | Each | |

| KH08102S141215 | 140 | 12 | 150 | 500 | ✔ | 1200 | Each | |

| KH08102S141220 | 140 | 12 | 200 | 500 | ✔ | 1200 | Each | |

| KH08102S161215 | 160 | 12 | 150 | 500 | ✔ | 1200 | Each | |

| KH08102S161220 | 160 | 12 | 200 | 500 | ✔ | 1200 | Each | |

| KH08102S191215 | 190 | 12 | 150 | 500 | ✔ | 1200 | Each | |

| KH08102S191220 | 190 | 12 | 200 | 500 | ✔ | 1200 | Each | |

| KH08102S191615 | 190 | 16 | 150 | 650 | ✔ | 1200 | Each | |

| KH08102S191620 | 190 | 16 | 200 | 650 | ✔ | 1200 | Each | |

| KH08102S241215 | 240 | 12 | 150 | 500 | ✔ | 1200 | Each | |

| KH08102S241220 | 240 | 12 | 200 | 500 | ✔ | 1200 | Each | |

| KH08102S241615 | 240 | 16 | 150 | 650 | ✔ | 1200 | Each | |

| KH08102S241620 | 240 | 16 | 200 | 650 | ✔ | 1200 | Each |

-

Startabox, 80mm box x H12 x 200mm centres

-

Startabox, 110mm box x H12 x 150mm centres

-

Startabox, 110mm box x H12 x 200mm centres

-

Startabox, 140mm box x H12 x 150mm centres

-

Startabox, 140mm box x H12 x 200mm centres

-

Startabox, 160mm box x H12 x 150mm centres

-

Startabox, 160mm box x H12 x 200mm centres

-

Startabox, 190mm box x H12 x 150mm centres

-

Startabox, 190mm box x H12 x 200mm centres

-

Startabox, 240mm box x H12 x 150mm centres

-

Startabox, 240mm box x H12 x 200mm centres

-

Startabox, 110mm box x H16 x 150mm centres

-

Startabox, 110mm box x H16 x 200mm centres

-

Startabox, 190mm box x H16 x 150mm centres

-

Startabox, 190mm box x H16 x 200mm centres

-

Startabox, 240mm box x H16 x 150mm centres

-

Startabox, 240mm box x H16 x 200mm centres